SMT has designed various specifications of section steel production lines for customers, including single specifications and multiple specifications, such as I-beam, angle steel, channel steel, T-shaped steel, etc. The traditional rolling production line technology is very mature, and we have a full set of technology and experience. on the basis of traditional process, SMT applies the self-developed Pre-Slitting rolling patented technology to the section steel production line. Higher billeting efficiency liberates the design capacity of the rolling mill, the unique roll design reduces the consumption of spare parts, and the configuration of the finishing mill is more flexible and specific.

Compared with the traditional section steel production line of the same capacity, it effectively reduces the direct investment of the production line. The production capacity design of different specifications is more flexible, and the production line consumes less energy. Small-scale production lines can even run directly through generators, with higher production efficiency, lower operation and maintenance costs, and unparalleled market advantages.

With our Pre-Slitting technology we support our customers in achieving prime quality levels without compromises.

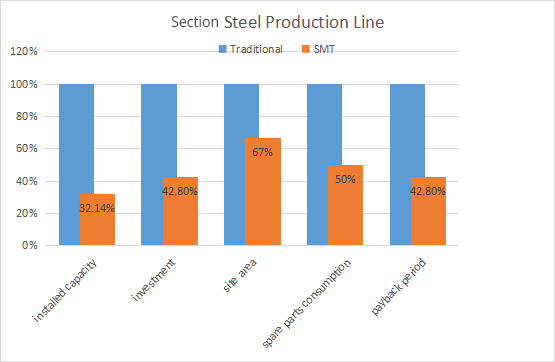

Investment comparison between SMT with traditional bar production line as follow

Remarks: The comparative data is based on the same production capacity