SMT has designed a variety of wire production lines for global customers. We have rich experience in design、manufacturing、construction、 and operation etc.. We are fully capable of continuing to provide services to customers with traditional technology and equipment, but now SMT has developed more economical and garanted process technology and equipment, the patented technology of Pre-Slitting independently developed by SMT can be well integrated with wire rod production lines. SMT Pre-Slitting rolling technology is a combination of a special roll pass design and guide equipment to shape and longitudinally separate the incoming billet into 2, 3, 4 or 5 individual bars. These are then rolled respectively down to the finished size in the finishing mill stands, simultaneously cut into fixed length or make a round by recoiling reel.

Compared with traditional wire rod production lines, the new wire rod production lines using Pre-Slitting technology will greatly reduce investment costs, especially the investment cost of small wire rod production line will be greatly reduced, The production specification design is more comprehensive, and the production line layout is more flexible without increasing the equipment, with lower energy consumption, and can even run directly through a generator.

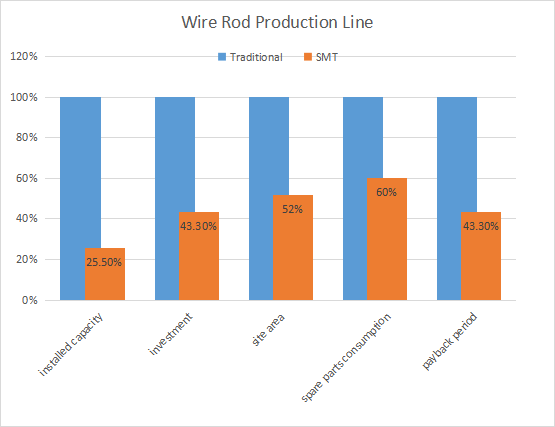

Investment comparison between SMT with traditional bar production line as follow

Remarks: The comparative data is based on the same production capacity